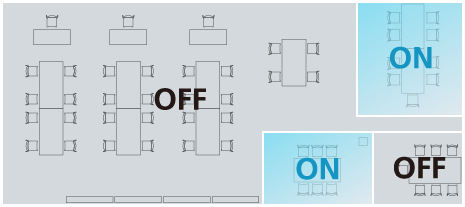

Air Condition Only Where IT'S Needed

VRV Changed the History of Air Conditioning

In the past, getting on a ship was the only way to travel overseas. However, today, flying on an airplane has become the standard.

From time to time, new standards are born through innovations.

“Daikin’s development of VRV”

It was the moment a new standard was created;

the birth of the next generation of air conditioners.

*VRV is a trademark of Daikin Industries, Ltd.

“Until the last person leaves, central air conditioning could not be turned off”

In the past, central air conditioning was the only way to air condition the buildings.

Those were the days where hundreds of thousands of empty rooms around the world

were unreasonably air conditioned.

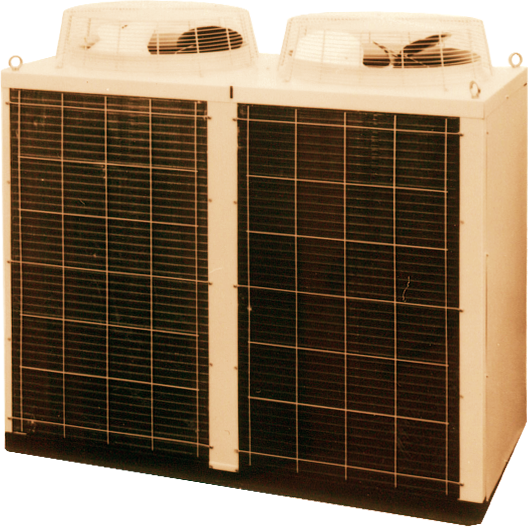

1982 VRV - The Opening of the Era of New Air Conditioning Standard

Daikin developed VRV, the world’s first multi-split type air conditioner for commercial buildings.

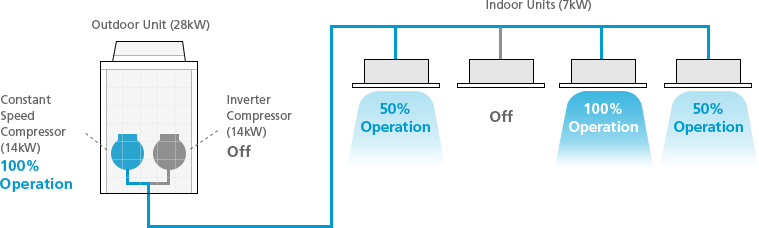

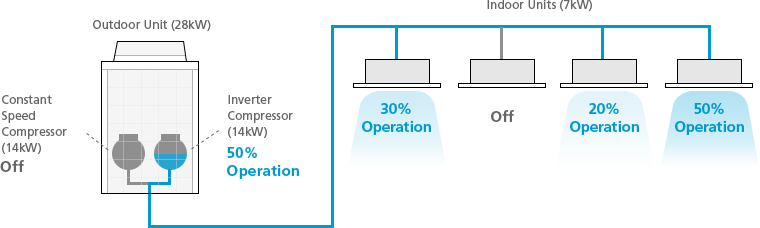

The realization of individual zone control was believed to be a huge challenge, until the arrival of VRV. This epoch-making development has drastically innovated air conditioning standard of commercial building.

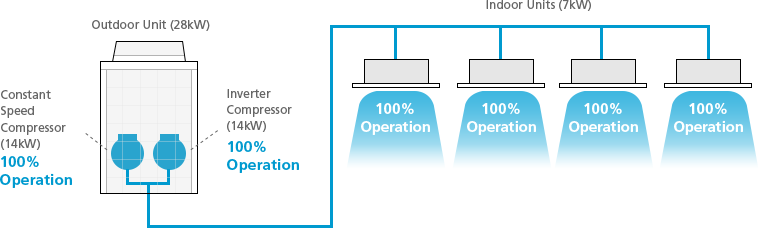

By air conditioning only occupied rooms, VRV ensures both “energy savings” and “comfort.”

“To achieve greater energy efficiency and comfort”

1986 Lower electric bills, greater comfort level

By using an inverter that operates with enhanced precise temperature control and efficiency, VRV air conditioner greatly cuts energy costs and realizes an even more comfortable environment.

“To adapt to diverse building layouts”

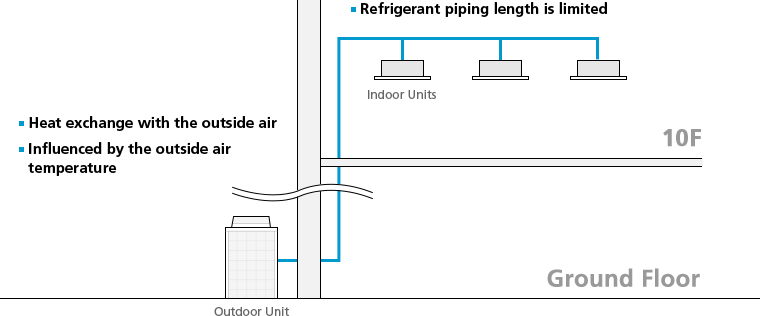

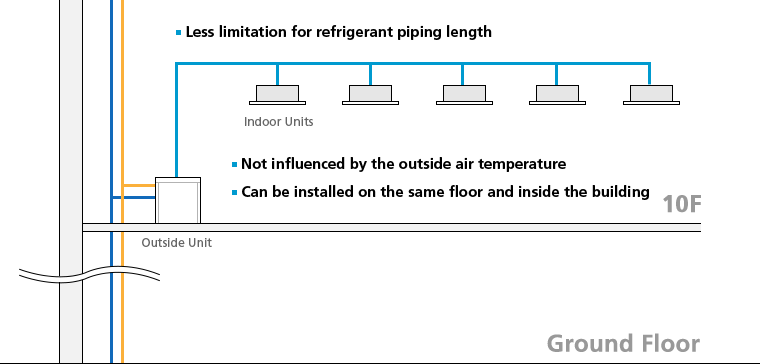

1990 The outdoor unit that is installable anywhere

Daikin developed the water-cooled VRV air conditioner. VRV enabled the outside unit to be paled indoors, and now can easily be installed even in high-rise buildings.

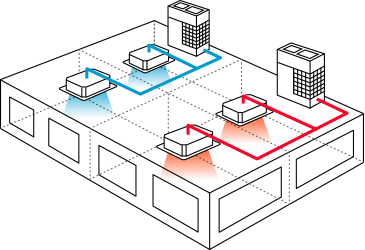

“To respond to diverse preferences at the same time”

1990 Those who are sensitive to temperature can be satisfied together

With heat recovery VRV air conditioner, simultaneous operation of heating and cooling with one outdoor unit became possible. Daikin realized enhanced comfort to buildings with diverse air conditioning needs, such as hotels, where people gather from all around the world.

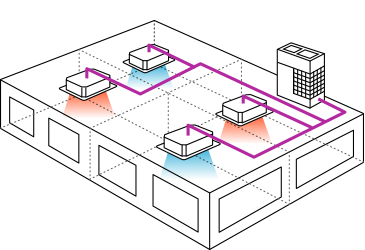

“To have replacement done easily”

1999 Surprisingly quick replacement process

Daikin developed VRV air conditioner, which can be installed just by replacing indoor and outdoor units reusing existing refrigerant piping. This development reduces the time of installation and minimizes the impact on retail businesses, which often operate 24 hours a day.

“To spread the benefits of life with VRV”

1999 Bringing coolness to extremely hot regions

Daikin has brought VRV air conditioner to where outdoor temperatures rise to 50 °C. Centering on the Middle East, Daikin has spread VRV in this hot climate region.

2007 Bringing warmth to extremely cold regions

For severely cold environments which temperatures drop as low as -25 °C, Daikin developed a highly efficient heat pump type VRV air conditioner. Daikin expanded the experience of VRV to the extremely cold regions, where combustion heating prevailed.

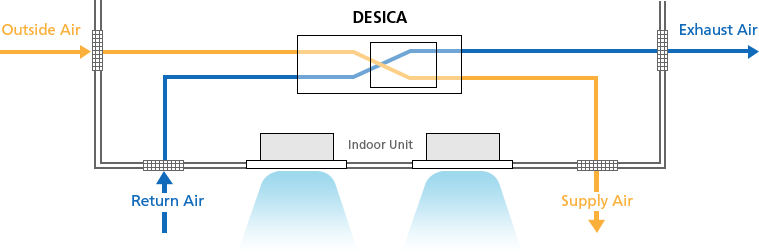

“To achieve ultimate comfort”

2007 Controlling even humidity

As a result of multilaterally pursuing "more comfort", Daikin has enabled the control of humidity by VRV system with DESICA, heat pump desiccant.

This system has been installed also in such places as art museums and libraries, which require precise humidity control.

What Daikin created was an ultimately new type of air conditioning.

Today, it has become one of the two types of

air conditioning systems, ducted and ductless, in the world.

Daikin will always be the pioneer of air conditioning and continue to expand this new standard, from building to building, around the world.

VRV Evolution by Specifications

1982 |

2016 |

|

|---|---|---|

| Cooling Capacity | 28 - 70kW | 11 - 150kW |

| Energy Efficiency (Cooling COP, EER) |

2.78 | 3.28 |

| Maximum Number of Connectable Indoor Units | 10 | 64 |

| Maximum Distance between Outdoor Unit and Indoor Unit | 50m | 165m |

Source: Daikin.com